While I have been fermenting mead for a while now, this is my first mead fermented under pressure.

Shown here the mead is in secondary waiting for it to clear.

Please note that I like my mead as dry as possible. If I want to sweeten it, later I will add some stevia or other non-fermentable sweetener. Most of the time I like it dry.

The Recipe

Let’s take a look at this particular recipe.

Initial Mix Day 1

First, I added 13 Lbs. of (Non-Raw) clover honey (Purchased locally) to my pressure vessel.

I then added 2 gallons of hot water. This is well water from my tap. I gave it a good mix with a long plastic stirring spoon.

I then added 2 cups of black tea made with 5 tea bags.

I then added 3 tsp of LDC yeast nutrient.

I added enough cold water to take it to 5 gallons and mixed well. I then took a reading and got a SG of 1.105. This is a little too high ABV for me, so I added another gallon of water taking it to 6 gallons. My new SG reading was 1.092.

I then added about 10 oz of whole raisins and the zest from half of an orange.

I used a small aquarium pump and an air stone and aeriated for 30 minutes.

While the aerating, In a separate cup, I mixed 1 Pkg 71B yeast with 2 oz of warm water and 1 oz of my current water/honey mix. I also added 1/2 tsp of LDC yeast energizer. This needs to rest for about 20 minutes.

(Note that have some issues using yeast energizer that I will get into in my second mead pressure fermentation)

Once the aeration is complete, I pitched the yeast mix on to the top of the main mixture (must).

I closed up the fermenter and added my spunding valve set to 15 PSI.

I placed the fermenter in a room with a temp set to about 70 degrees Fahrenheit.

I don’t add any pressure to the vessel. I let it build on its own. The yeast needs the oxygen to get things going. In this particular ferment, It reached 15PSI in just a few hours.

Day 3

I released the pressure using the pressure relief valve and removed the lid and added 3 more tsp of LDC yeast nutrient.

I also took a SG reading of 1.030.

I resealed the lid and let the must come back to pressure on its own.

I am experimenting with ways of pulling samples and adding nutrients without removing the lid or all the pressure in the fermenter.

This involves using a small tap to pull a sample and a pressurized bottle holding the nutrients and forcing them into the fermenter.

Day 6

On day 6 the mead was completely dry at just under 1.0. This will yield me a mead at 12.14%.

I had some solids floating in my mead and wanted to remove them while the mead is in secondary.

To remove the grapes and peels, I could have used some sort of sterilized plastic strainer inserted into the lid but decided to do a closed pressure transfer from on pressure vessel to another.

I picked up a couple of these small picnic taps to let me dispense the mead for testing as it ages. This will allow me to take readings and taste as needed.

Note that the vessel will lose pressure over time as the CO2 is absorbed into the mead. It will also loose a little pressure each time the tap is used.

I will top off the pressure using my Co2 tank. I will keep it between 10 and 15 PSI as it goes through secondary.

Moving Forward

I tasted the mead and it’s young and has a bit of carbonation. I am curious as to how the final taste profile turns out as it clears and ages a little.

I am keeping this mead covered and in a cool place for clarification and a little aging.

Since this is my first-time doing things this way, I have it near my kegerator and C02 source.

I have attached the spunding valve and if it drops below 15PSI, I top it off as needed.

Note that I do not have the tap connected as these can leak a little C02 over time. I connect it as needed, then remove it.

The temperate is running about 57F.

Currently it will not fit in my small kegerator.

Day 14

Day 15

Day 16

On day 16, mead is drinkable, but a little young. The mead is at 61 degrease Fahrenheit. It is a little young and needs to age. I think its diminishing returns since i done have a way to cool the whole fermenter at this time. I will transfer to carboy soon for aging.

Moving Even Further

It is possible to cold crash the mead and actually age and serve the mead directly from the Fermzilla. There are a couple problems with this.

I don’t have a fridge that the Fermzilla will fit.

I don’t want to tie up one of my Fermzillas for a couple months while I age the mead.

On day 17, I moved the mead from the Fermzilla to a glass carboy.

I did a closed transfer using Co2 at about 3 psi to move the mead to a purged carboy with a transfer cap.

The liquid out (floating Dip Tube) connected to a racking cane in the transfer cap. On the secondary port on the transfer cap, I connect a spunding valve set to about just over the psi the C02 tank is generating.

It’s a little slow but it keeps the oxygen out of the system.

Day 28

Mead is about a month old. I decided to pull some out and to a taste test.

It is still slightly carbonated from the pressure fermentation. It still tastes young and needs to age at least another month.

I will chill and fully carbonate this one to see how it presents itself.

Day 37

After tasting the mead again, I decided to cold crash it for a while. Unfortunately, I don’t have space in any of my fridges for a 5-gallon carboy, so I racked it into smaller containers.

I moved it into 3 1-gallon carboys, and a 2.5 gallon keg.

Day 41

I just finished a delicious crystal-clear mead I made a few months back. I looked it up in my journal. The only difference between that mead and others that had taken for ever to clear, was that I had added Campden tablets.

I decided to do an experiment and added a dissolved Campden tablet to each gallon of mead.

I added a tablet to the mead on the right a week before all the others. As you can see it is starting to clear. It looks like it is clearer than the ones where I added a tablet a week later.

Day 44

The three, 1-gallon carboys are clearing up very well. The 2 gallons in the keg even more. In addition, it tastes really good.

I will decant the keg and drink it as the three carboys continue to age.

Day 70 …. Final Update

Well, here I am 70 days after I started this batch. It turned out as one of my favorite meads. Out of the 5 gallons, all have been consumed with great joy. All that is left is this last gallon, that I will store away for a rainy day.

Wait! I think it’s raining now.

Equipment I used

Before closing, I want to go over the equipment I used.

Disclosure: I often use Amazon affiliate links for some of the items I have listed. Purchasing from these links adds no additional cost to you but helps me support this website.

My goal is to eventually get a large stainless steel conical. Before taking that plunge, I wanted to experiment with pressure fermenting mead on a smaller (and cheaper) scale.

This is the pressure fermentation vessel that I used. I feel it’s the least expensive ways to get into pressure fermentation. Note the Fermzilla is pressure capable, and you will need to purchase a few more items if you want to ferment under pressure.

As it comes you can do un-pressurized fermentations out of the box.

Note that you can also use a cornelius keg in the exact same way. You can get them used or new and they already come with the Ballock posts. You will still have to purchase the floating dip tube. It comes with the parts to connect to the cornelius keg.

These caps screw onto the posts provided in the lid of the Fermazilla. They literally turn the Fermazilla into a keg.

As the mead ferments it will start to build pressure. You need a way to control the amount of pressure that builds up by bleeding off the excess. A spunding valve is used for this purpose. This one works very well.

Tubing for spunding valve bubbler

I like watching the activity in an air lock to gauge the activity in my ferments. By attaching this tubing to the spunding valve and into a jar of water, you can see the bubbles from the excess Co2.

Fermzilla Floating Dip Tube and Filter

While not required to pressure ferment, this dip tube attachment will allow you to take samples and transfer your mead to other vessels. If you have a fridge large enough to hold the Fermzilla, you can even use it to dispense for finished mead.

While you can use a spoon or other devise to add oxygen to your initial must, I have found a small air pump and air stone works so much better.

These are pretty cheap, and work very well. They are used to add oxygen to aquariums. Remember to spray some sanitizer on these before placing them in your must.

Used to connect the air stone to the air pump.

Never use a metal spoon inside your fermentation vessel. They will cause small scratches that will make it impossible to properly clean the fermenter.

This is the tank that I purchased. It has worked perfectly. In my area it costs me about $25 to fill.

Note that you can ferment under pressure without a C02 Tank. But I have to say once you get one you won’t ever go back.

While you can certainly find cheaper regulators, you can’t go wrong with a Taprite regulator.

You need this to connect the regulator to your pressure vessel.

Other Links

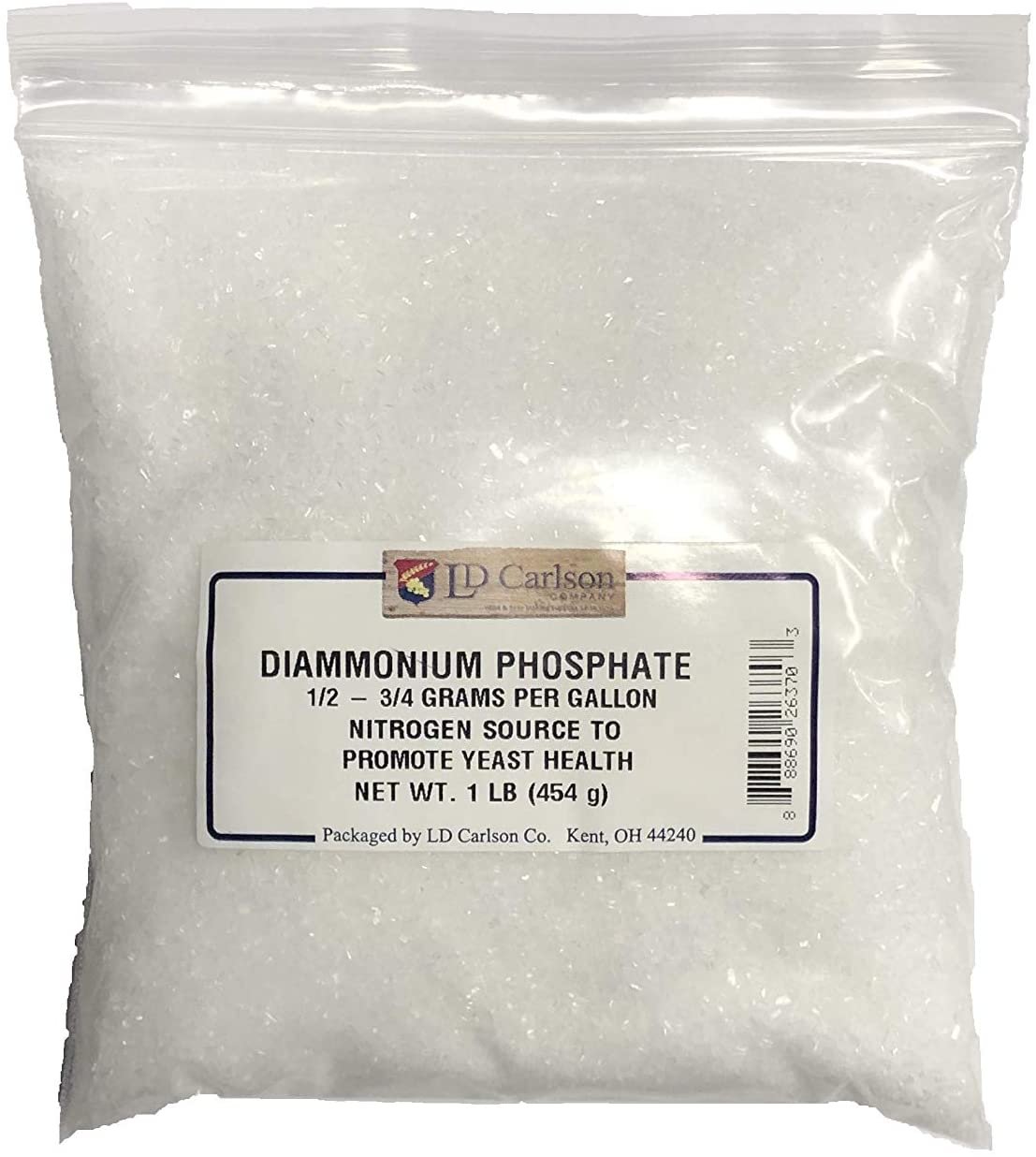

This is the nutrient that I used. Others will work as well.

In the past I have only used diammonium phosphate (DAP) and decided to try this one. It contains both urea and diammonium phosphate. That said from research I have found it contains quite a bit more uria than diammonium phosphate. This is not a good thing as uria is good as a plant fertilizer but not so good for you in fermentation.

In the future I am going to go back to my DAP, especially since the pressure fermentation has gone so well.

This is the one I used.

While totally optional, I have found that this can help get the yeast of to a fast start.

I have had mixed results using this yeast energizer. I will be changing my procedure for using it or eliminating it completely.

I have found that 71B yeast allows the mead to mature more quickly than some of the others that I have tried. It does work well under pressure. I will be experimenting with other yeasts as well.